The failure of the manufacturing sector to attain the objective of labor-intensive exports can be attributed to a confluence of factors that have impeded the sector’s growth. One major contributing factor is the pervasive shift towards capital-intensive production methods, driven by advancements in technology and automation. This trend has diminished the demand for labor-intensive manufacturing, rendering traditional industries less competitive in the global market. Additionally, inadequate skill development programs and outdated labor policies have hindered the workforce’s adaptability to emerging industries. To reverse this trend and foster more labor-intensive exports, strategic measures need to be implemented. Investing in skill enhancement programs and vocational training to align the workforce with the demands of labor-intensive industries is crucial. Furthermore, reforming labor policies to provide flexibility and incentives for businesses to engage in labor-intensive production can stimulate growth in this sector. Adopting a proactive approach towards technological integration while preserving a balance between capital and labor-intensive methods will be pivotal for revitalizing the manufacturing sector and achieving the desired export goals.

Tag: Indian economy and issues related to planning, mobilization of resources, growth development and employment.

Contents

Decoding the Question:

- In Intro, try to highlight the contribution of the manufacturing sector.

- In Body,

- Discuss reasons for the failure of the manufacturing sector in achieving the goal of the labor-intensive sector.

- Suggest measures for increasing labor-intensive sector export.

- Try to conclude with the need to increase exports from labor intensive sectors.

Answer:

The Indian manufacturing sector has seen a transition from the initial industrialisation to license raj to liberalization and the current phase of global competitiveness. A key lacuna in India’s growth has been slow growth of manufacturing in labor-intensive sectors and concentration in capital intensive manufacturing sectors like auto parts, chemicals, software and pharmaceuticals. None of these sectors employ low-skilled workers in large numbers.

India’s share of global manufacturing stands a little over 2% compared to China’s contribution of 22.4% percent.

Indian Labor-intensive Manufacturing: It is an industry that requires a large amount of labour to produce its goods like food processing, tobacco, textiles, apparel, leather. In 2004-05, the low-value added labour-intensive enterprises were 35 percent of organized manufacturing employment in India.

But, there is a continuous decline in total factor productivity of low-value added labour-intensive enterprises since 1991. The reasons for decline could be due to absorption of more unskilled labour force in the sector.

Reasons for lower labor-intensive export:

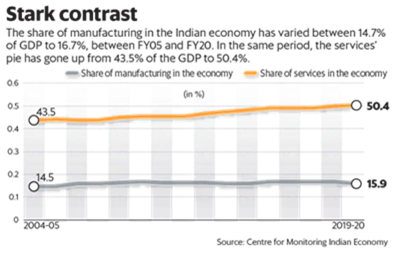

1. Shift to Services Sector:

- Services Sector Share in GDP: According to India’s Economic Survey 2022-2023, the services sector accounted for over 50% of India’s Gross Domestic Product (GDP).

- Export Contribution: The services sector, including IT services, BPO, and software exports, has consistently been a major contributor to India’s total export earnings. In the fiscal year 2021-2022, the services sector accounted for approximately 43% of India’s total exports, as reported by the Ministry of Commerce and Industry.

2. Rising Labor Costs:

- India’s labor costs have been increasing over the years. As of 2022, according to the Labour Bureau, Ministry of Labour and Employment the average daily wage rate in the organized manufacturing sector was around INR 473 (approximately USD 6.5). Labor reforms have been undertaken by various state governments in India to address issues related to labor costs and flexibility in labor regulations.

3. Automation and Technology Adoption:

- India has been actively adopting automation and advanced technologies in various industries. As of 2020, India’s robot density (number of robots per 10,000 employees) was relatively low at 3.7 robots. India’s electronics production was valued at around USD 70 billion in 2019-2020, with a target to reach USD 400 billion by 2025. (Source: Ministry of Electronics and Information Technology – MeitY) The use of robotics and automation has also been observed in industries like electronics manufacturing, textiles, and pharmaceuticals.

4. Economic Growth:

- In the manufacturing sector, India is considered a specialized and capital-intensive sector. Even though India’s true comparative advantage lies in unskilled labor-intensive activities. As of 2022, the service sector accounted for over 50% of India’s Gross Domestic Product (GDP), and As of 2022, the services sector employed around 34% of the total workforce in India.

5. Competitive Pressure from Other Economies:

- India faces competition from countries with lower labor costs, such as China and other Southeast Asian nations. This competition can impact India’s export performance in labor-intensive sectors like textiles, garments, and footwear.

- For example, in the fiscal year 2021-2022, India’s trade deficit with China was approximately USD 38.73 billion.

- As of 2022, China accounted for around 40% of the world’s total textile and apparel exports.As of 2021, Bangladesh was the second-largest exporter of ready-made garments globally, after China.

6. Government Policies and Trade Agreements:

- According to the Department for Promotion of Industry and Internal Trade (DPIIT),In the financial year 2021-2022, India attracted USD 81.72 billion of FDI, indicating positive traction for manufacturing and exports.

- According to the Ministry of External Affairs, Government of India, the Comprehensive Economic Cooperation Agreement (CECA) between India and Singapore in 2019-2020, India’s exports to Singapore were valued at USD 12.54 billion, and imports were valued at USD 10.44 billion, reflecting the trade benefits under the agreement.

- According to the Ministry of External Affairs, Government of India as of 2021, India’s trade with ASEAN was approximately USD 86.9 billion, with India’s exports to ASEAN valued at USD 32.18 billion and imports from ASEAN at USD 54.72 billion.

7. Skill Development and Human Capital:

- Under the Skill India Mission, the government aimed to provide skill training to over 40 crore (400 million) people by 2022. (Source: Ministry of Skill Development and Entrepreneurship)

- As of 2021, more than 1.2 crore (12 million) candidates had been trained under various skill development programs across different sectors in India. (Source: Ministry of Skill Development and Entrepreneurship)

- The Pradhan Mantri Kaushal Vikas Yojana (PMKVY) is one of the flagship skill development schemes, and by 2021, it has trained over 1 crore (10 million) youth with employable skills. (Source: Ministry of Skill Development and Entrepreneurship)

- In the financial year 2021-2022, the IT industry’s exports were valued at around USD 170 billion. (Source: NASSCOM).

8. Focus on Higher Value-Added Exports:

- The Indian government has been promoting sectors such as pharmaceuticals, engineering goods, electronics, and automobiles for higher value-added exports.

- According to the Pharmaceuticals Export Promotion Council of India (Pharmexcil), India exported pharmaceutical products worth approximately USD 24.4 billion in the financial year 2020-2021.

- In the financial year 2021-2022, engineering goods exports accounted for approximately USD 68.5 billion.

- As of 2022, India’s electronics exports were valued at around USD 13.2 billion, and the country aimed to significantly increase its electronics manufacturing capabilities and exports.

- In the financial year 2021-2022, automobile exports from India amounted to approximately USD 8.9 billion, as per data from the Society of Indian Automobile Manufacturers (SIAM)

Measures taken to promote labor-intensive manufacturing: To promote labor-intensive manufacturing in India, the government has implemented various schemes and acts to incentivize and support industries that generate significant employment opportunities. Here are some of the measures taken :

- Make in India Initiative: The Make in India initiative was launched in 2014 to boost domestic manufacturing and create employment opportunities. It focuses on attracting foreign direct investment (FDI) and encouraging domestic companies to invest in manufacturing sectors. According to the Department for Promotion of Industry and Internal Trade (DPIIT), between 2014 and 2019, FDI in India’s manufacturing sector increased significantly, leading to the creation of jobs and expansion of manufacturing activities.

- Pradhan Mantri Mudra Yojana (PMMY): PMMY was launched in 2015 to provide financial support to micro and small enterprises, including those in the manufacturing sector. It offers collateral-free loans to first-time entrepreneurs and small businesses. As of September 2021, PMMY had sanctioned over 31 crore (310 million) loans amounting to more than 17 lakh crore rupees (around 170 billion USD), benefiting a large number of small manufacturing units and promoting employment generation.

- Goods and Services Tax (GST) Reform: The introduction of GST in 2017 aimed to simplify India’s tax structure, enhance ease of doing business, and boost the manufacturing sector’s growth. According to the World Bank’s Ease of Doing Business report, India’s ranking in the “Paying Taxes” category improved from 172 in 2017 to 115 in 2020, reflecting the positive impact of GST on the ease of doing business.

- Production-Linked Incentive (PLI) Scheme: The PLI scheme, launched in 2020, provides financial incentives to eligible manufacturing companies in sectors such as electronics, pharmaceuticals, automobiles, and textiles. As of September 2021, the government had approved PLI schemes worth over 2 lakh crore rupees (around 20 billion USD) across various sectors, with a significant focus on labor-intensive industries.

- National Skill Development Mission: The National Skill Development Mission, launched in 2015, aims to provide skill training and upskilling to the Indian workforce, making them more employable in the manufacturing and other sectors. As of 2021, the National Skill Development Corporation (NSDC), under the Skill India Mission, had trained over 5 million individuals in various sectors, including manufacturing.

- Production-Linked Incentive (PLI) Scheme: The PLI scheme, launched in 2020, provides financial incentives to companies in labor-intensive sectors, such as electronics, pharmaceuticals, textiles, and automobiles. It aims to boost domestic manufacturing, increase exports, and create employment opportunities.

- Industrial Disputes Act, 1947: The Industrial Disputes Act provides a legal framework for the investigation and settlement of industrial disputes and labor-related issues. The act helps maintain harmonious industrial relations and provides stability for labor-intensive manufacturing industries.

- Apprenticeship Act, 1961: The Apprenticeship Act encourages the engagement of apprentices in industrial establishments, allowing young people to gain practical training and acquire relevant skills. This act fosters a skilled workforce for labor-intensive manufacturing industries.

The low-cost manufacturing and promotion of labor-intensive sectors are very essential for increasing exports especially from the labor-intensive sector. Various studies have estimated that every job created in manufacturing has a multiplier effect in creating 2–3 jobs in the services sector. Therefore, increasing exports from the labor-intensive sector is very significant for employment generation and makes India an export-dominated economy.

In case you still have your doubts, contact us on 9811333901.

For UPSC Prelims Resources, Click here

For Daily Updates and Study Material:

Join our Telegram Channel – Edukemy for IAS

- 1. Learn through Videos – here

- 2. Be Exam Ready by Practicing Daily MCQs – here

- 3. Daily Newsletter – Get all your Current Affairs Covered – here

- 4. Mains Answer Writing Practice – here