India’s semiconductor Industry future looks promising as the country gears up to become a key player in the global chip manufacturing industry. Semiconductors are essential components in electronic devices like smartphones, computers, and cars, and their demand is skyrocketing with the rise of new technologies. To reduce dependency on imports and strengthen its position in the tech world, India is investing heavily in building its semiconductor ecosystem. With government initiatives, foreign collaborations, and efforts to develop a skilled workforce, India aims to become a hub for semiconductor manufacturing, boosting both the economy and technological innovation.

Tags: GS-3, Economy- Growth & Development- Inclusive growth- Industry

Contents

- 0.1 Context:

- 0.2 What is the current scenario of the semiconductor industry in India?

- 0.3 What is the Significance of Semiconductors for India?

- 0.4 What are the Key Challenges in India’s Semiconductor Path?

- 0.5 What Steps can India Undertake to turn its Semiconductor Vision into a Reality?

- 1 UPSC Civil Services Examination, Previous Year Question (PYQ)

- 2 To get free counseling/support on UPSC preparation from expert mentors please call 9773890604

Context:

- The government launched the semiconductor industry in 2021 with vital national security investments in areas such as defence and telecommunications with US$10 billion.

- Geopolitical tensions and the Covid-19 pandemic highlighted the risks of foreign semiconductor imports from Taiwan , the emphasis on over-reliance on Japan’s presence is South Korea.

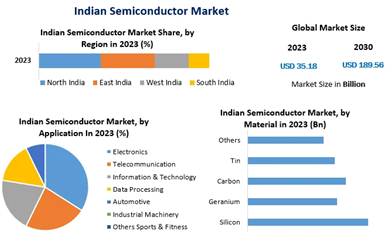

What is the current scenario of the semiconductor industry in India?

- Current status of semiconductor industry in India:

- Market : The market size in 2022 is estimated to be around US$. $26.3 billion

- Forecasted Growth: To reach US$271.9 billion by 2032, at a CAGR of 26.3%.

- Imports: 2021: $5.36 billion

- Exports: 2022: $0.52 trillion.

- Government Services:

- India Semiconductor Mission (ISM): A division under Digital India Corporation dedicated to building a robust semiconductor and display ecosystem.

- 50% of the operating costs of financial support for semiconductor fabs and display fabs.

- Semicon India Strategy: Launched in December 2021 with an investment of ₹76,000 crore ($9.2 billion) to increase production of semiconductors and displays.

- To support further growth, the FY24 budget has been increased to ₹6,903 crore ($833.7 million).

- International Collaboration:

- Holds discussions with the European Commission on strengthening the semiconductor ecosystem as part of the EU-India Trade and Technology Council.

- MOC and Japan will strengthen the semiconductor supply chain flexibility between the two countries.

What is the Significance of Semiconductors for India?

- Economic Growth and Industrial Development

- Semiconductors are critical to India’s electronics manufacturing, aiming for a significant share of the global market projected to hit USD 1 trillion by 2030.

- The 2021 USD 10 billion Semiconductor Mission could create 35,000 direct and 100,000 indirect jobs, boosting electronics manufacturing to USD 300 billion by 2026.

- Technological Self-Reliance and Innovation

- India imports 65-70% of electronic components, mainly from China.

- Initiatives like the Design Linked Incentive (DLI) aim to foster domestic innovation, crucial for 5G, AI, and quantum computing.

- Global Supply Chain Integration

- India’s semiconductor initiatives seek to enhance its 3% contribution to the global electronics value chain.

- Policies like Production-Linked Incentives (PLI) aim to attract global players and integrate India into international supply networks.

- Job Creation and Skill Development

- The semiconductor sector can create high-quality jobs and promote STEM education.

- Specialised skills in chip design, nanofabrication, and advanced packaging will drive skill development in cutting-edge technologies.

What are the Key Challenges in India’s Semiconductor Path?

- Infrastructure Challenges

- India’s uneven infrastructure, including unreliable power, water scarcity, and poor transport, hampers semiconductor plant operations.

- For example, power shortages during the 2024 heat wave affected industrial activities, including semiconductor manufacturing.

- Talent Gap

- Despite India’s engineering talent, there is a shortage of semiconductor experts.

- By 2027, India may face a deficit of 250,000 to 300,000 skilled semiconductor professionals, limiting ecosystem growth and global manufacturer attraction.

- High Manufacturing Costs

- Setting up semiconductor plants in India is more expensive than in established hubs like Taiwan or the U.S.

- Costs rose 4.9% in 2021 and 2.4% in 2022, making India less attractive for global semiconductor investments.

- Global Supply Chain Dynamics

- The semiconductor industry’s reliance on a global supply chain makes India vulnerable to disruptions, like the Russia-Ukraine conflict’s impact on neon supply, crucial for chip manufacturing.

- Ensuring a stable supply of raw materials and components is vital for success.

- Environmental Concerns

- Semiconductor production is energy-intensive, contributing to 31% of global greenhouse gas emissions.

- India’s focus on sustainable development creates challenges in balancing environmental concerns with industry growth.

- Competition from Other Emerging Markets

- India faces competition from countries like Vietnam, Malaysia, and Indonesia, which offer better incentives and infrastructure.

- Malaysia, for instance, attracted major companies like Infineon in the first wave of semiconductor investments.

What Steps can India Undertake to turn its Semiconductor Vision into a Reality?

- Enhance Semiconductor Education and Training

- Expand semiconductor engineering programs and partners like IISc Bangalore could collaborate with Taiwan Semiconductor Manufacturing Company with practical learning via state-of-the-art facilities.

- Develop Indigenous Chip Design Capabilities

- Set up chip design centres in tech hubs like Bangalore, Hyderabad, and Pune, and incentivize startups.

- The success of IIT Madras’ Shakti processor highlights India’s potential, and expanding similar initiatives can boost domestic chip design.

- Create a Robust Semiconductor Supply Chain

- Establish SEZs for the semiconductor ecosystem, offering tax breaks and streamlined regulations to global companies like Applied Materials or Lam Research.

- Establish a Sovereign Semiconductor Fund

- Launch a sovereign & Capital fund can prioritise cutting-edge technologies like 3nm and 2nm fabrication, positioning India at the forefront of innovation, similar to South Korea’s approach.

- Implement a “Chip Diplomacy” Strategy

- India could partner with Japan to establish a joint semiconductor research centre for advanced packaging, helping overcome technology acquisition hurdles.

- Develop a “Green Semiconductor” Initiative

- Partner with firms like Applied Materials to set up pilot fabs using recycled water and renewable energy, attracting environmentally conscious investors and aligning with global sustainability trends.

- Establish a National Semiconductor Commons

- A national network of nanofabrication facilities, similar to the US NNIN, would foster innovation in chip design and manufacturing, promoting collaboration between academia, industry, and government.

UPSC Civil Services Examination, Previous Year Question (PYQ)

Prelims:

Q:1 Which one of the following laser types is used in a laser printer? (2008)

- Dye laser

- Gas laser

- Semiconductor laser

- Excimer laser

Ans: (c)

Q:2 With reference to solar power production in India, consider the following statements: (2018)

- India is the third largest in the world in the manufacture of silicon wafers used in photovoltaic units.

- The solar power tariffs are determined by the Solar Energy Corporation of India.

Which of the statements given above is/are correct?

- 1 only

- 2 only

- Both 1 and 2

- Neither 1 nor 2

Ans: (d)

Source: BS

To get free counseling/support on UPSC preparation from expert mentors please call 9773890604

- Join our Main Telegram Channel and access PYQs, Current Affairs and UPSC Guidance for free – Edukemy for IAS

- Learn Economy for free- Economy for UPSC

- Learn CSAT – CSAT for UPSC

- Mains Answer Writing Practice-Mains Answer Writing

- For UPSC Prelims Resources, Click here